As received

As received |

Look

left Look

left |

Look right

Look right |

Broken Ferrite Antenna support quickly repaired with Hot Melt glue

gun. Replacing and stringing the dial cord was a different

matter.

Broken Ferrite Antenna support quickly repaired with Hot Melt glue

gun. Replacing and stringing the dial cord was a different

matter. |

Out of the cabinet shot.

Out of the cabinet shot. |

I ALWAYS store the dial glass separately. I do not want an accident

and have to find a replacement!

I ALWAYS store the dial glass separately. I do not want an accident

and have to find a replacement! |

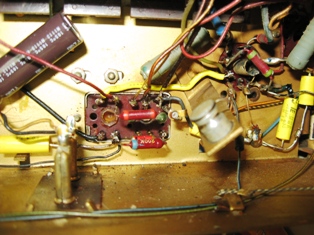

The blue capacitor just under the left side of the switch enclosure was

shorted. You can also see the burnt (open) 1k ohm resistors that the

short took out.

The blue capacitor just under the left side of the switch enclosure was

shorted. You can also see the burnt (open) 1k ohm resistors that the

short took out. |

The

yellowed paper capacitors can be seen under side. The blue

capacitors are also paper inside. The

yellowed paper capacitors can be seen under side. The blue

capacitors are also paper inside. |

Restored and working. Products on the left used to shine the knob brights

and treat the plastic. Glass cleaner took care of the dial

glass. TEST the paint before cleaning.

Restored and working. Products on the left used to shine the knob brights

and treat the plastic. Glass cleaner took care of the dial

glass. TEST the paint before cleaning. |

No flash and Light Out shot.

No flash and Light Out shot. |

Sorry. I did not take a picture of the

restored under chassis. I will post one if I disassemble the unit

again. All the paper and blue capacitors have been replaced with

yellow tubular caps that are considerable smaller in size but all

rated at 630 volts. |

In the picture directly above, between

the two horizontally oriented blue caps, is a dark circle with three

wires. Two electrolytic capacitors mounted to a new terminal strip

replace the chassis mounted can capacitor. The wires were moved to

the terminal strip and the can cap left in place for appearance

sake. Again sorry for not taking an after picture. See the Capacitor

Page for an example. |

This is the flat pack selenium rectifier bridge removed from the

radio. A screw driver, pliers and a soft touch will slip the cover

off.

This is the flat pack selenium rectifier bridge removed from the

radio. A screw driver, pliers and a soft touch will slip the cover

off. |

Once the cover clears the bottom metal container the top flies across the

table and little square metal pieces shower back down on your bench.

Those are the selenium wafers.

Once the cover clears the bottom metal container the top flies across the

table and little square metal pieces shower back down on your bench.

Those are the selenium wafers. |

Trim the contacts so one pad per solder contact remains. Drill two

holes in each to receive the 1N4007 lead wires.

Trim the contacts so one pad per solder contact remains. Drill two

holes in each to receive the 1N4007 lead wires. |

I tapes and labeled the solder pads in accordance to the stamped terminal

identifiers in the metal cover plate (the one that shot across the

bench).

I tapes and labeled the solder pads in accordance to the stamped terminal

identifiers in the metal cover plate (the one that shot across the

bench). |

Install and solder all four diodes.

Install and solder all four diodes. |

Reassemble making sure all the insulating materials are returned inside

the metal enclosure or a high voltage short will occur. That's it!

Reassemble making sure all the insulating materials are returned inside

the metal enclosure or a high voltage short will occur. That's it! |

As Received. |

As Received (the flash lightened the cabinet color. |

Restored. |

Nice dial scale. And sounds great too! Trust me on this

one. |

Cleaned with Deodorized Mineral spirits to remove wax, dirt and

grime. |

Various stain pens used to darken chips and scratches. |

A coat of hand rubbed paste wax.... |

...and a nice buffing. |

She cleans up nicely. |

|

Record the wiring point. |

Original parts |

Ugh, Dirt. |

Stuffed 1N4007 diodes inside the selenium bridge case. |

All B+ voltage right on the mark with the fuse at 125vac. No

series resistor needed. |

The moving coil on this IF can will not move. Document wire connections

before removing can. |

Yep. That's the culprit. Simple cleaning did not work. So

it has to be repaired. |

No luck on the chassis so off it comes. This photo shows

orientation of the transormer. |

|

Those Germans sure know how to make an elegant IF transformers. |

The rod on the right is stuck. |

|

A good flush does not work. |

Nor does a good scrubbing. |

Sand off the corrosion from the top of shaft, No go. |

Now for the drill bit. |

It scraped off some rough spots. |

The shaft now moves easily. This is Caig Fader Lube. |

This lube is used on slider pots. I works great on the brass to

plastic interface. |

Just like new! |

It has been re-installed and works great with the treble control. It

only retracts about 1/8 inch. |

All caps have been replaced, all resistors tested. |

FM tuner

All good inside. I re-tensioned the tube socket. The pins

were loose. |

Clean. No paper caps here. All resistors test good and in

tolerance. |

This socket has been rewired to accommodate an EM80. The EM80 has

the same electrical/performance specs as the original EM85. |

Time for a clean up! Wipe on Clorox Clean Up. |

This is a deep untreated scratch into the wood. It was darkened with a

stain pen. |

|

The Tweeter received an internal overhaul.

You can't hear this picture but trust me, it sounds great! |

New plumber's washers used on the chassis retaining bolts. It isolates

the metal chassis from the wood cabinet (a little bit). |

The speaker selector needed the wiper contacts burnished. Several

on the chassis cleaning attempts did not get rid of an intermittent

problem. It is all gone now! |

|

Schematic Diagram.

Schematic Diagram.![]()